Some bricks have pictures of more than one face (see final column).

To see the pictures click on the thumb nails . If you just want to look through the pictures without coming back to the table, use the arrows at the bottom of each page to see the next or previous brick

Brick makers often stamped the bricks with a distinctive mark, usually in the frog (depression on the top), but occasionally on the side. I have identified many makers from the marks, but a few are either illegible, or I can't find any reference to a maker using such a mark.

Click on the images to get a bigger picture (or pictures - see right hand column).

| No |

Maker |

Inscription |

Found |

Notes |

Approx size (mm) |

Click image to enlarge |

Pics |

| 55 |

Accrington Brick & Tile Co, Huncote Accrington |

ACRINGTON NORI |

Wallsend, Northumberland |

NORIs are iron hard engineering bricks. (NORI is iron spelt backwards) |

66x101x214 |

|

1 |

| 74 |

Allan & Mann, Glasgow |

.........ANN

.....OW |

Inveraray |

Half brick |

85x105x? |

|

1 |

| 60 |

Ibstock Brick, Ashdown Brickworks, Bexhill, E Sussex |

ASHDOWN |

Wokingham, Berks |

New build 2012 |

60x100x215 |

|

1 |

| 107 |

H J Baldwin Brickworks, Bunny, Notts |

BALDWIN

METRIC |

Earley, Berks |

|

65x110x213 |

|

1 |

| 100 |

Bovingdon Brickworks, Hemel Hempsted, Herts |

BB |

Wokingham, Berks |

|

63x100x215 |

|

1 |

| 41 |

Binfield Brick & Tile Company, Binfield Berks |

BB • TC |

Wokingham, Berks |

|

70x110x230 |

|

1 |

| 37 |

Cadder Brick Company Limited, Glasgow |

CADDER |

Glasgow |

Burn marks, coloration |

86x108x230 |

|

2 |

| 108 |

The Clock House Brick Company (Capel Surrey) |

CAPEL |

Wokingham, Berks |

Cracks on reverse |

63x100x210 |

|

2 |

| 72 |

CHH? |

CHH |

Bexley, Kent |

Decorative edge |

68x100x210 |

|

3 |

| 85 |

Darby Brick Co. Samuel Darby,Victoria Brickworks, Beccles, Suffolk |

DBC |

Donated by Keith Thompson (South Ascot, Berks) |

|

63x110x225 |

|

2 |

| 12 |

Eastwoods, Peterborough |

EASTWOODS

FLETTONS |

|

|

63x105x217 |

|

1 |

| 47 |

JC Edwards of Ruabon |

J . C . E |

Nant Clwyd estate, Wales |

Bull nose |

77x105x225 |

|

1 |

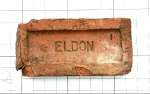

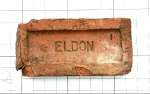

| 1 |

Eldon brickworks, Bishop Auckland, Co Durham |

ELDON |

Old works near Collier Law, Co Durham |

Black mortar |

70x110x225 |

|

1 |

| 50 |

Freshfield Lane Brickworks, Danehill Sussex |

FLB |

Nuffield, Oxon |

In timber building frame (French) |

66x140x215 |

|

1 |

| 44 |

Furness Brick and Tile Co., Barrow-in-Furness |

FURNESS BRICK

CO LD

BARROW |

Copper mines valley, Coniston |

Mould marks |

78x111x233 |

|

2 |

| 121 |

Benjamin Holmes, Kirkby in Ashfield, Notts |

HOLMES

KIRKBY |

CWS Hosiery factory, North Street, Huthwaite (Donated by Martyn Fretwell) |

Plinth stretcher |

80x110x238 |

|

3 |

| 93 |

Hudsons, West Hoathly Factory, Sharpthorne, E Grinstead, W Sussex (now owned by Ibstock) |

HWH |

Donated by Keith Thompson (South Ascot, Berks) |

|

65x100x215 |

|

1 |

| 7 |

Ibstock Brick, Ltd, Ibstock, Leics |

IBSTOCK |

Wokingham, Berks |

1976 (~ Desford) |

64x100x215 |

|

3 |

| 40 |

Ibstock Brick, Ltd, Ibstock, Leics |

IBSTOCK |

Wokingham, Berks,1985 |

Note holes not in 1975 brick |

60x92 x214 |

|

3 |

| 2 |

Jones Bros. Pelaw, Co Durham |

JONES BROS

PELLAW |

|

|

75x110x230 |

|

1 |

| 119 |

Ketley Brickworks, Brierly Hill |

TLEY 06 |

Ketley Brickworks (reject) |

Inscription sideways on side face |

68x102x215 |

|

3 |

| 66 |

Keymer Brick & Tile Works, Burgess Hill, W Sussex |

KEYMER |

Pinkneys Green, Berks |

Ridges on reverse |

65x101x222 |

|

2 |

| 61 |

(?Possibly Kier & Cawder?) |

K&C |

Inveraray |

On beach |

75x107x223 |

|

1 |

| 104 |

Unknown |

L |

Wokingham, Berks |

Under floor of All Saints Church |

65x108x223 |

|

1 |

| 105 |

Unknown |

L |

Wokingham, Berks |

Under floor of All Saints Church |

65x108x225 |

|

1 |

| 86 |

Leeds Fireclay Co Ltd |

LEEDS | FIRE CLAY CO | LTD = ENGLAND = |

Donated by Keith Thompson (South Ascot, Berks) |

|

70x110x230 |

|

3 |

| 14 |

London Brick Company |

LBC

PHORPRES |

|

Key grooves, plaster |

65x115x217 |

|

1 |

| 15 |

London Brick Company |

LB-01-90 |

|

Sand faced Fletton |

60x100x210 |

|

2 |

| 16 |

London Brick Company |

LONDON

BRICK |

|

Sand faced Fletton |

62x100x210 |

|

2 |

| 75 |

London Brick Company |

LONDON

BRICK |

|

Common brick with kiss marks on side |

60x100x225 |

|

2 |

| 101 |

London Brick Company, Marston Vale |

MARSTON |

Wokingham (Caroline Drive) |

Sand faced Fletton |

65x105x225 |

|

3 |

| 103 |

Henry George Matthews, Bellingdon Bucks |

• HGM • |

Wokingham, under floor of All Saints Church |

|

65x100x? |

|

1 |

| 114 |

Henry George Matthews, Bellingdon Bucks |

• HGM 8 : |

Wokingham, used in repair of All Saints Church |

|

66x107x224 |

|

1 |

| 73 |

Middleton Colliery, Leeds |

(a) ME&Co-LEEDS-LTD-ENGLAND

(b) MIDDL-ETON-LEEDS |

Wokingham (Garrick Wood in rubble) |

Stamp on top & bottom. Part glazed |

70x110x225 |

|

3 |

| 5 |

NCB Desford, Leics |

NCB DESFORD |

Wokingham, Berks |

1955 note colour |

63x103x220 |

|

3 |

| 6 |

NCB Desford, Leics |

(NCB DESFORD) |

Wokingham, Berks |

1955 note colour |

63x103x? |

|

2 |

| 91 |

Pinewood Estate Brick & Tile Co. (Little Hungerford or Hermitage, Berks) |

PINEWOOD |

Donated by Keith Thompson (South Ascot, Berks) |

|

65x100x220 |

|

1 |

| 106 |

?? |

R |

Wokingham, Berks |

Under floor of All Saints Church |

67x108x225 |

|

1 |

| 3 |

?? |

ROBSON |

Old works near Collier Law, Co Durham |

|

60x110x225 |

|

1 |

| 87 |

Snedshill Brickworks, Lilleshall Company, ShropshireSB |

SB |

Donated by Keith Thompson (South Ascot, Berks) |

Green glazed face |

70x110x230 |

|

2 |

| 122 |

Stonehouse Brick & Tile Co.Ltd, Stonehouse Glos |

STONEHOUSE BRICK & TILE CO LD |

Donated by Andy |

|

68x110x230 |

|

2 |

| 92 |

Southwater Brick, Tile, Terra Cotta, Pipe & Clay Co. Ltd, Horsham, Sussex |

SOUTHWATER |

Donated by Keith Thompson (South Ascot, Berks) |

|

63x100x212 |

|

1 |

| 90 |

?? |

ST |

Donated by Keith Thompson (South Ascot, Berks) |

|

70x110x225 |

|

1 |

| 94 |

Straker & Love, Newcastle on Tyne |

S&LBCo |

Donated by Keith Thompson (South Ascot, Berks) |

|

65x105x225 |

|

1 |

| 56 |

Warnham Brickworks, Horsham,Sussex |

WARNHAM

SBC |

Wokingham, Berks |

|

67x105x220 |

|

2 |

| 8 |

Thomas Lawrence, Bracknell, Berks |

TLB |

Broadmoor, Berks (found with 9) |

Different shape/size |

70x113x202 |

|

1 |

| 9 |

Thomas Lawrence, Bracknell, Berks |

TLB |

Broadmoor, Berks (found with 8) |

Different shape/size |

64x102x218 |

|

1 |

| 95 |

Thomas Lawrence, Bracknell, Berks |

TLB 29 |

Donated by Keith Thompson (South Ascot, Berks) |

Shaped corner |

70x115x230 |

|

1 |

| 96 |

Thomas Lawrence, Bracknell, Berks |

TLB 7 |

Donated by Keith Thompson (South Ascot, Berks) |

Chamfered corner |

70x115x230 |

|

1 |

| 102 |

Thomas Lawrence, Bracknell, Berks |

TLB 17 |

Wokingham, Berks |

Rubble under 1920s floor of All Saints church |

65x112x? |

|

2 |

| 113 |

Thomas Lawrence, Bracknell, Berks |

(a) TLB

(b) PATENT |

Wokingham, Berks |

Sharp lettering |

70x110x225 |

|

2 |

| 82 |

Thomas Lawrence, Bracknell, Berks (probably) |

.... 20 |

Wokingham, Berks |

Rubble under 1920s floor of All Saints church |

?x?x? |

|

1 |

| 22 |

Thomas Lawrence, Bracknell, Berks (probably) |

TLB

? |

Wokingham, Berks |

Demolished site of AC Barnes, Oxford Road |

66x103x215 |

|

1 |

| 21 |

Thomas Lawrence, Wokingham, Berks |

* WK * |

Wokingham, Berks |

Machine made, Asymmetric frog on obverse |

67x107x222 |

|

1 |

| 109 |

Thomas Lawrence, Wokingham, Berks |

... WK * |

Wokingham, Berks |

Rubble under 1920s floor of All Saints church |

68x100x? |

|

2 |

| 110 |

Thomas Lawrence, Wokingham, Berks |

* ... |

Wokingham, Berks |

Rubble under 1920s floor of All Saints church |

70x?x? |

|

3 |

| 111 |

Thomas Lawrence, Wokingham, Berks |

* ... |

Wokingham, Berks |

Rubble under 1920s floor of All Saints church |

70x?x? |

|

3 |

| 11 |

Wealden factory, Horsham, West Sussex |

WEALDEN |

|

Burns & distortion |

60x100x220 |

|

1 |

| 13 |

Ockley Brick Co Ltd, Smokejacks Brickworks,Wallis Wood, Nr. Dorking |

<>-<> |

|

Blisters, burning, kiss marks

Known as 'Double Diamond' brick |

62x95 x213 |

|

1 |

| 26 |

?? |

MWH |

|

|

62x98 x212 |

|

1 |

| 53 |

Wealden factory, Horsham, West Sussex |

WEALDEN |

? |

Distortion, heating |

65x100x215 |

|

1 |

| 83 |

Star Brick & Tile Co |

STAR

NEWPORT |

Shirenewton |

Keyed inner face |

65x105x220 |

|

2 |

Click on the images to get a bigger picture (or pictures - see right hand column).

Modern bricks are often perforated. It reduces the weight and also reduces the energy needed to heat through the brick when firing it.

Click on the images to get a bigger picture (or pictures - see right hand column).

Paving bricks differ from wall bricks in several ways. They are normally much thinner and made of a harder material, to resist damage from damp. They have a hard wearing top surface, which is often patterned to help drainage and provide a better grip.

You can click on the images to get a bigger picture (or pictures - see right hand column).

Pictures of all of these are shown below.

Click on the images to enlarge.

Over the years I have accumulated bricks found in diverse places – over 120 by 2023 – and they come in many shapes, sizes and colours (click to see larger image). The pictures below are all at the same scale, and taken against a 1" grid, to reflect the actual differences in their sizes. I try to find out what I can about them all but if you think I've got something wrong, or you can provide more information then please contact me .

Over the years I have accumulated bricks found in diverse places – over 120 by 2023 – and they come in many shapes, sizes and colours (click to see larger image). The pictures below are all at the same scale, and taken against a 1" grid, to reflect the actual differences in their sizes. I try to find out what I can about them all but if you think I've got something wrong, or you can provide more information then please contact me .