The Tower Handbook

14.8: Ropes

a: What attention do ropes need?

Ropes wear out faster than anything else. You can't stop them wearing, but good housekeeping can ensure they do not fail prematurely. You will get different problems above and below the sally so there is a question on each.

b: How can we reduce rope wear above the sally?

Synthetic top ends greatly extend the rope life (see section 14.8o & section 14.8q). If everything the rope comes into contact with is in proper order it will ensure you do not needlessly shorten the rope's life. Top ends tend to wear in three places.

- Where they go through the garter hole in the rim of the wheel

The stress and continual bending are both concentrated here. The wheel has a radiused fillet to reduce the tightness of the turn as the rope enters the wheel and this spreads the load a little, but it is still concentrated within about 50mm (2 inches). Raise or lower the ropes every now and again so the damage is spread out over more of the rope. This will prolong its life. You will need to adjust the tail ends when you do this.

- Where they pass over pulleys (less frequent)

The pulleys impose bending and some friction on the ropes, but it is spread over a longer length of rope, as the rope passes through. The worst places are the parts of the rope that are near the pulley when you are pulling at hand or backstroke. If the pulley sticks there will be a lot more wear on the rope. If the rope wears a groove in the pulley this wear will increase dramatically. If you see signs of wear here, make sure you find the cause rather than just replace the rope. Badly worn pulleys will also cause the rope and possibly the bell to misbehave. See section 14.6d.

- Where they pass through holes and guides

The holes for the ropes to go through floors and rope guides should all have smooth wooden or metal bosses to prevent snagging and minimise friction. Sometimes there is no boss but just a hole cut through the boards. In many cases this causes no problems, but if the rope run is not perfectly straight, the rope can wear a groove in the side of the hole. This can produce corresponding wear of the rope, especially if the groove wears deep or if the floor board is moved so the rope wears more heavily or against a part of the hole that has not been worn smooth. Very rarely a wooden boss may crack providing sharp edges for the rope to rub on.

Check your ropes every couple of months for signs of wear [227]. Don't be lulled into a false sense of security just because they have been OK for several years. The longer they last, the nearer they are to the end of their lives!

c: Why do some ropes have a leather sleeve round the rope?

This is one way to reduce wear on the rope where it goes through the garter hole. To make one, cut a piece of soft leather to about 150mm (6 inches) long and make it wide enough to wrap once round the rope while laid lengthwise along it. Then bind it round the rope and stitch the joint along the length of the sleeve. Slide the sleeve into position so that it goes through the garter hole, and secure it with insulating tape or thin twine. You should be able to get off-cuts of leather from a saddlery.

d: How can I prolong rope life below the sally?

To an extent, whether you get rope problems below the sally depends on how successful you are above the sally. Traditional ropes normally fail aloft before they fail in the ringing room. There are two common problems with tail ends.

- Damage caused by tucking

Most of the tail end is double which helps share the load, but tucking the tail end through the rope distorts it. In a three strand rope, the distortion is uneven with one strand on one side and two on the other. At the top tuck, the rope changes from double to single and this causes a concentration of stress at the tuck. If you leave the tuck in the same place for a prolonged period, this point will weaken and be the first point of failure. You can reduce this risk by moving the tuck occasionally but not too often since each time you disturb the rope fibres you do some damage.

- Damage caused by hitting the floor

If the floor is rough or the rope catches the rough edge of a box, the scuffing will wear it. A carpet or ringing mat [228], and smoothing the edges of boxes, will help avoid this. If tucking has weakened the rope, as above, being pounded on the floor will often finish it off. What a healthy rope can stand, one with a weak spot can't.

e: How can I stop tucks coming undone?

If you are the steeple keeper, it is very embarrassing when someone's rope comes untucked during ringing. The tucks are only held in place by friction. Your hands pull both parts of the rope and if the free end can move, each pull will cause it to creep by an imperceptible amount that eventually causes it to come untucked. The cure is to use enough tucks to spread the load so that the force you put on the bottom of the rope is dissipated before it gets to the top tuck. A loosely laid rope [229] (ie with the strands more loosely twisted together) will need more tucks. Always end with a double tuck, ie two close together at the top, since this gives the best protection against slipping.

Some people fasten the end with sticky tape to deter anyone moving the tuck. This damages the rope. The taped portion is stiffer and concentrates the stress at its top end. This causes wear tempting you to tape a little higher and so on. Every time you remove the tape it rips out some of the fibres.

f: How can I stop the rope end fraying?

The traditional way is to whip the rope with twine. This produces a high quality job and ropes supplied to you will normally be whipped. Any book on rope craft will show you how to do this. There are other ways. Tying the end with twine is less neat but will often suffice. Squeezing a latex based solution such as Copydex into the ends of the strands and then squeezing and twisting the rope end together gives a quick and fairly durable result providing you squeeze the glue well into the end [230]. With synthetic ropes, you have the extra option of fusing the fibres at the end together by heating them in a flame to melt them. You will need to hold the end together while you do this or the three strands will each fuse neatly but not be joined together. Take care not to touch the resulting hot sticky blob with dry fingers or you will get burnt.

g: Why do bits of fluff come off the sallies?

There could be several reasons. Large tufts of wool dropping on the floor mean something is wrong. It is most likely the sally is catching, probably where it passes through a hole or a rope guide. Alternatively it could mean that the rope is breaking up within the sally, see below. If you get a small amount of very fine fluff on the floor, especially when the sallies are new, it is probably not serious and may stop once the sallies have bedded in. But don't ignore it if it persists.

h: Do sallies ever break?

The wool jacket protects the rope inside to a large extent, so like old soldiers, old sallies tend to fade away, ie they get thinner especially in the middle where they are held most often. But they are not indestructible. If you have synthetic top ends and you replace your tail ends, there will come a time when the sally fails. The most likely place is just inside the top. This is where the rope takes the shock of the bump every time the sally goes through the rope guide. The first you will notice is a piece of rope fibre sticking out rather more stiffly than the bits of wool that sometimes become detached from it. Sadly there is little you can do [231] but retire the sally to act as a door stop, switch pull or other ornament. You can reduce the impact caused when the sally passes through the rope guide if you specify a more gradual taper on the end of the sally when it is made.

i: Why do ropes seem to fail very quickly?

Ropes go for a long time with little sign of wear. When they do start to fail two things happen that hasten the rate at which the whole rope breaks up.

- When one strand starts to weaken it stretches a little and that leaves more stress on the others.

- When the fibres in the rope start to break up that part of the rope becomes looser and more flexible than the rest, so it takes more than its fair share of the bending. This is especially true in the tail end.

j: Do you need to put lubricant on the ropes?

Rope lubricant is an oily compound intended for use with natural fibre ropes. It soaks into the fibres. It stops them drying out and prevents internal chafing. If your bell chamber is prone to condensation or exposed to the weather then rope lubricant is worth putting onto the rope near pulleys and the garter hole. You can get proprietary products from rope suppliers. Don't overdo it, though.

k: Can I repair broken ropes?

In most cases you can save a lot of expense by repairing a rope, instead of buying a new one. Knots would foul guides and pulleys etc as they went through them, so repair invariably means splicing [232]. Splices are used either to rejoin a break or to replace a portion of worn out or damaged rope with a new piece.

In most cases you can save a lot of expense by repairing a rope, instead of buying a new one. Knots would foul guides and pulleys etc as they went through them, so repair invariably means splicing [232]. Splices are used either to rejoin a break or to replace a portion of worn out or damaged rope with a new piece.

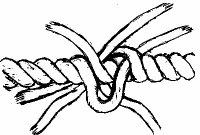

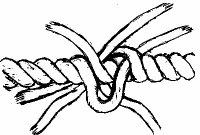

There is a lot of mystique about splicing, but it's really quite simple to do. If you are likely to be in a situation where you are called upon to repair a rope. Don't rely on someone else always doing the job for you. Find out for yourself! Even if there is no one in your tower to teach you, there is bound to be someone in the next tower or in your local branch who can help you. Alternatively, consult one of the many books on ropes, knots and splices. Repairs can only last so long though – see picture.

A splice is a way of joining rope without the lumps that would be caused by a knot. All splices involve un-twisting the strands of the rope end and then 'weaving' these in between the strands of the piece it is being joined to.

m: How do I do a splice?

Only splice good rope. If you are mending a broken rope, it is quite likely that the rope either side of the break will be worn or de-natured, so always examine it to see whether it is fit for reuse. Cut off any that is not. If this (and the length consumed by the splice) will make the rope too short, then you will have to splice on a replacement piece of rope. This happens most often with tail ends where there is much less spare length.

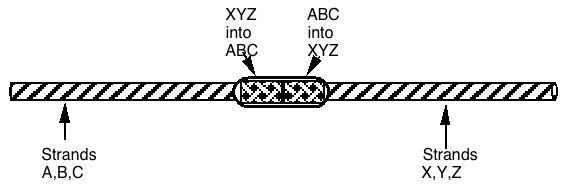

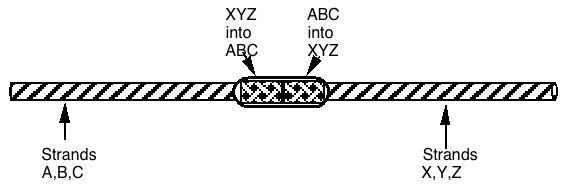

Unwind the strands for about 200mm (8 inches) at the rope end. Put the two ends together so the strands alternate from the two ends see picture. Make sure they fit snugly. You will find it easier to handle if you tie or tape one set of strands to the rope so they don't get in the way while you work with the others.

Unwind the strands for about 200mm (8 inches) at the rope end. Put the two ends together so the strands alternate from the two ends see picture. Make sure they fit snugly. You will find it easier to handle if you tie or tape one set of strands to the rope so they don't get in the way while you work with the others.

From here, each strand must go over and then under a strand of the rope it is being worked into. The picture shows making the first tuck This is simple and neat when you get it right, but very easy to make a slip, so be methodical and keep checking as you go. If you make a mistake, undo it and check before going on. Try to keep the ends of the strands from unfraying. If they do that, things get much harder.

From here, each strand must go over and then under a strand of the rope it is being worked into. The picture shows making the first tuck This is simple and neat when you get it right, but very easy to make a slip, so be methodical and keep checking as you go. If you make a mistake, undo it and check before going on. Try to keep the ends of the strands from unfraying. If they do that, things get much harder.

Always tuck each of the three [233] strands once before moving on to use any again for the next pass. After each pass the three strands should be evenly spaced round the rope, each emerging between a separate pair of strands in the rope. Check that they are, work out any kinks and pull all strands tight and even. [234] If the rope is loose, twist it to hold the strands together after every pass. After three passes, split about a third of the fibres out of each strand and cut them off before making the next pass. Then remove another third before the final pass. This gives you a tapering end.

When you have done one end, repeat the process with the other, first making sure the strands are tightly in place. When the splice is complete trim off all the loose tufts and roll the splice between your hands (or under your foot on the floor) to bed in any unevenness.

You will probably need to practise several splices before you get the knack. Use fairly soft rope for your initial trials. Hard rope is much more difficult because it takes a lot of force and/or cunning (with or without a marlin spike) to get the strands far enough apart to put the tucks through.

n: Are all splices the same?

There are different forms of splice for different jobs.

- Short splice

This is the most basic and most useful. It is 100 to 150mm (4 to 6 inches) long including tapered ends.

- Long splice

This is really three [235] short partial splices spread out along about 600 mm (2 feet) of rope. The smaller increase in thickness disrupts the smooth flow of the rope less and so it is preferred [236] for joins that need to pass through pulleys.

Eye splice 1

Eye splice 1

This forms a small loop or 'eye' on the end of the rope. It is not traditionally used in ringing, but you can use it to replace tail ends without cutting back into the rope every time to do a new short splice. Splice an eye below the sally and then splice one through it on the new tail end (see left diagram). Next time you replace the tail end, cut away the lower eye, leaving the other intact.

Eye splice 2

Eye splice 2

It is tempting to go a step further (see right hand diagram) with two loops threaded through each other. This allows tail ends to be swapped without any cutting, but it is more bulky (worse than a permanent figure-of-eight knot) and it can knock your knuckles or catch your finger nails while ringing.

- Back splice

This is probably never seen in towers. The rope is spliced back into itself. It is a deluxe way of providing a neat end to a rope.

o: Should we use synthetic ropes?

Traditional bell ropes are made of hemp or flax [237]. They wear, are very springy when first fitted, and expand and contract as the weather gets drier or wetter. Ropes made from synthetic fibres can overcome many of these problems. Synthetic top ends for bell ropes are made of pre-stretched polyester. This is also known under the brand names of Terylene or Dacron. If you are buying the rope yourself, make sure you get the pre-stretched variety (for obvious reasons), even though it is a little more expensive. There are two grades of pre-stretching (from different makers). One is more pre-stretched than the other, but both have been used satisfactorily for top ends. Under no circumstances use nylon, which is a very springy rope [238].

Synthetic top ends far outlast natural fibre. They are a boon in towers with long draughts which suffer severe springiness or length changes with the weather. They are also invaluable in very hot humid climates where natural fibres tend to rot, or cold humid climates where the ropes tend to be rigid. Stiff ropes can cause special problems if you have heavily drawn [239] ropes. The stiffness makes them fly out rather than going smoothly round the bends.

The other common synthetic rope is polypropylene. In its usual form this is a fairly cheap, rough rope commonly used for tying things on the back of lorries and not suitable for ringing. A more refined form of polypropylene is sold under the brand name Hempex [240] (as a substitute for hemp). It looks and feels very like hemp but with a slightly harder fibre. Hempex has been used for tail ends [241] (see below). The 12mm gauge is more suitable than 10mm, because it is easier to grip.

p: Can the whole rope be made of synthetic material?

Polyester, as used for top ends, is a soft, slippery rope, unsuitable for tail ends. No one has found a way of putting sallies into polyester ropes. Normal practice is to use natural fibre from a foot or two above the sally to the tail end.

Some people have tried tail ends of Hempex. It behaves very much like hemp, but wears well and remains soft even when old. Some ringers dislike it because it does not absorb sweat, is lighter than hemp (and probably just because it is different).

On the other hand not going stiff by absorbing moisture could be a major improvement if your tower is very damp. See picture

On the other hand not going stiff by absorbing moisture could be a major improvement if your tower is very damp. See picture

There are rumours of synthetic ropes wearing [242] pulleys (especially nylon ones). Another concern is that they may snag on rough pulleys or bosses, leading quickly to break down. We have no details of such incidents, but know of towers still using synthetic top ends after ten or fifteen years of heavy use. As they wear, the worn fibres remain attached to the rope, making it look a little furry. This contrasts with hemp where worn fibre is either shed or packed into the gaps between the strands leaving a smooth, hard rope that gets thinner as it wears, until it starts to break up. If you are thinking of changing and want reassurance, get advice or talk to people who have used them.

q: Can you splice synthetic rope into hemp?

Yes. There is a myth that you can't, but it has been done and works well. Some bell rope manufacturers twist the fibres together before the rope is laid up, giving an almost invisible join (sometimes misleadingly called 'machine splicing'). If you buy the new rope to splice onto a good sally and tail end, you do not have this option. The two types of rope have different properties (the synthetic rope is softer and more slippery) so you need a little more than an ordinary short splice. Make it longer than normal (say 5 passes each side), and make the taper much more gradual (say 4 passes each end).

r: How do I work out the length of replacement ropes?

This may sound like a silly question, but quite often people buy ropes and then find they are the wrong length. Think of the rope in three sections:

- The tail end and sally

- The bit between the top of the sally and the garter hole

- The bit the other side of the garter hole

The middle section is easy to measure. Below the sally allow enough rope for easy adjustment, especially if you have learners and keep taking the ropes up and down. 3 to 4 metres (10 to 12 feet), or twice the diameter of the wheel is reasonable. The easiest length to get wrong is inside the garter hole, where the rope ties round the upright spokes of the wheel. 5 metres (16 feet) is not excessive. The extra rope provides some spare, not just for the splice when the rope breaks, but so you can move the splice down below where the wear is occurring, eg the garter hole or pulley. It's cheaper to buy a few extra feet of rope at the beginning than to get a whole new when it first breaks!

When you order ropes remember to give the weight of the bell(s), since this may affect the thickness of the rope you need.

Always keep some spare ropes for emergency. Hang them somewhere well ventilated. If you use natural fibre ropes, it helps to pre-stretch them so they are less springy when you first use them. Fastening a rope at the top of the stairs with a weight of say 10 - 20 kg tied to its end is one way of doing this.

s: What can we do about damp ropes?

Synthetic material improves the mechanical properties of the rope (see above) but a damp rope is still unpleasant to handle. Some towers in very humid climates keep their rope ends in a plastic bag with desiccant when not in use. This keeps the ropes dry. You can dry out the desiccant in an oven and then re-use it.

Previous

Next

Next

Currently hosted on jaharrison.me.uk

In most cases you can save a lot of expense by repairing a rope, instead of buying a new one. Knots would foul guides and pulleys etc as they went through them, so repair invariably means splicing [232]. Splices are used either to rejoin a break or to replace a portion of worn out or damaged rope with a new piece.

In most cases you can save a lot of expense by repairing a rope, instead of buying a new one. Knots would foul guides and pulleys etc as they went through them, so repair invariably means splicing [232]. Splices are used either to rejoin a break or to replace a portion of worn out or damaged rope with a new piece. Unwind the strands for about 200mm (8 inches) at the rope end. Put the two ends together so the strands alternate from the two ends see picture. Make sure they fit snugly. You will find it easier to handle if you tie or tape one set of strands to the rope so they don't get in the way while you work with the others.

Unwind the strands for about 200mm (8 inches) at the rope end. Put the two ends together so the strands alternate from the two ends see picture. Make sure they fit snugly. You will find it easier to handle if you tie or tape one set of strands to the rope so they don't get in the way while you work with the others. From here, each strand must go over and then under a strand of the rope it is being worked into. The picture shows making the first tuck This is simple and neat when you get it right, but very easy to make a slip, so be methodical and keep checking as you go. If you make a mistake, undo it and check before going on. Try to keep the ends of the strands from unfraying. If they do that, things get much harder.

From here, each strand must go over and then under a strand of the rope it is being worked into. The picture shows making the first tuck This is simple and neat when you get it right, but very easy to make a slip, so be methodical and keep checking as you go. If you make a mistake, undo it and check before going on. Try to keep the ends of the strands from unfraying. If they do that, things get much harder.

Eye splice 1

Eye splice 1 Eye splice 2

Eye splice 2 On the other hand not going stiff by absorbing moisture could be a major improvement if your tower is very damp. See picture

On the other hand not going stiff by absorbing moisture could be a major improvement if your tower is very damp. See picture