The Tower Handbook

14.9 Bell

a: Do the bells themselves need maintaining?

Bells need virtually no maintenance, and when they do it is always beyond the scope of a DIY job. If they crack, they may need recasting, though these days cracked bells can be welded reliably using a very slow heating and cooling process before and after the weld. If they are out of tune that too is a professional job.

b: How are bells tuned?

They are mounted on a very big lathe and small amounts of metal are removed very carefully from the inside. The bell vibrates in a complex way and the different components of the sound (partial tones) are affected by the thickness of different parts of the bell. Removing metal from one area may have a big effect on one partial and very little effect on another, so they can be tuned separately by taking metal from different places. It is not quite this simple, because each change has a small effect on several other partials as well as the one it mainly drives. See The Sound of Bells

c: What is quarter turning?

The repeated impact of the clapper on the soundbow wears a pit at the point of impact. This process is very slow, but if left the pit could eventually become deep enough to risk damaging the bell by starting a crack. The cure is to take out the bell and re-hang it turned through 90_ (ie a quarter of a turn) so the clapper strikes on a fresh pair of surfaces. Sometimes, when the second lot of pits has been worn, a bell will be 'eighth turned', ie 45_ to find yet another pair of undamaged places for the clapper to strike. Obviously these are not DIY jobs, and the complications of drilling new holes etc to fix the bell can be considerable. You can tell whether any of your bells has been quarter turned by looking for impact pits other than where the clapper now strikes.

d: What can I do about an odd-struck bell?

It is worth trying to cure odd struck bells since they have a big impact on the quality of striking that you can produce. Odd striking [243] is caused by misalignment or imbalance between the bell and the clapper (see section 5.1b). What you can actually move to improve the situation depends on your bells and how they are hung.A drastic solution for odd struck bells – see picture?

It is worth trying to cure odd struck bells since they have a big impact on the quality of striking that you can produce. Odd striking [243] is caused by misalignment or imbalance between the bell and the clapper (see section 5.1b). What you can actually move to improve the situation depends on your bells and how they are hung.A drastic solution for odd struck bells – see picture?

- Moving the clapper pivot

- If you have cast-in crown staples you cannot move the pivot.

- With central clapper bolts and wooden headstocks you can try inserting tapered fibre washers between the staple and the crown of the bell.

- If the bolt and staple are slightly bent then turning the assembly the other way round may make a difference (but it may make it worse). See section 14.7d for caution about removing clappers.

- If you have a modern headstock with twiddle pins you can adjust them. See section 14.7c.

- Moving the bell axis

The bell axis is most likely to move with bells strapped to old timber headstocks. If the bolts have not been adequately tightened, or have been tightened too much on one side (see section 14.12a on nut tightening) the bell may not be quite square on the headstock. Alternatively the timber may have warped. By carefully slackening the nuts on one side and tightening them on the other [244], you can move the bell slightly. The amount of movement you can achieve is limited since all you are doing is exploiting the slight misfit between the bell and the timber. This is not an amateur job, so take advice before trying it.

- Moving the centre of gravity

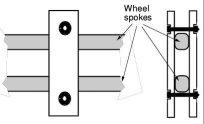

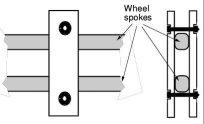

You can artificially move the centre of gravity by attaching a weight to the wheel (see picture). A modest weight can make a significant difference [245]. Near the rim it has considerable leverage [246]. The simplest pattern is two steel bars or plates clamped securely to either side of the pair of horizontal spokes. This can be very effective, but seek advice before trying it. The weights put extra forces on the wheel and if they were to come loose the consequences would be serious. This method needs quite a lot of trial and error to find out how much weight is needed, and where. Put the weight on the rope side of the wheel if the bell is late at handstroke, and vice versa.

The things above have all found some success, but there is no guarantee that you will be able to make enough adjustment to cure your problem. These are not simple maintenance tasks, so get advice before trying them.

e: How can I tell whether a bell is odd struck?

By ringing it. If the ringing rest of the ringing is even, a competent ringer will notice the need to apply extra correction at one stroke or the other to maintain even striking. If no one has a problem, then the bell is not odd struck enough to matter. If you decide to try correcting an odd struck bell, as above, you will need a method of measurement that can be used between adjustments. There are two ways.

- Measure the gaps

Remove the rope (or support its weight) and measure the distances between the clapper and the point at which it hits the bell on each side. In an even struck bell they should be the same. This is simple in principle, but in practice can be difficult because of the confined space and the fact that the clapper moves if you touch it with the end of your ruler. It is also not completely reliable if bell and clapper are both mis-aligned.

- Swing the clapper

With the bell down, hold the clapper against each side of the bell in turn and let it go. It should not swing far enough to hit the other side. If it does (one way), the bell is quite odd struck. This is a rough and ready test that is very easy to do. It may not tell you if the bell is only slightly odd struck (especially if the clapper is stiff).

- A dynamic test

Raise the bell by hand without a rope and then let it ring itself down. Observe whether the bell stops clappering on one side before the other. This method is more reliable, but never try it unless you have been shown how to do it by someone who knows the safe way to do it. We do not describe the safe way here, because getting it wrong could be fatal.

Previous

Next

Next

Currently hosted on jaharrison.me.uk

It is worth trying to cure odd struck bells since they have a big impact on the quality of striking that you can produce. Odd striking [243] is caused by misalignment or imbalance between the bell and the clapper (see section 5.1b). What you can actually move to improve the situation depends on your bells and how they are hung.A drastic solution for odd struck bells – see picture?

It is worth trying to cure odd struck bells since they have a big impact on the quality of striking that you can produce. Odd striking [243] is caused by misalignment or imbalance between the bell and the clapper (see section 5.1b). What you can actually move to improve the situation depends on your bells and how they are hung.A drastic solution for odd struck bells – see picture?