The Tower Handbook

14.7 Clappers

Although there are many subspecies, clappers really come in two flavours:

- Those attached to cast-in crown staples

The cast-in staple is a piece of wrought iron shaped like three sides of a square and cast into the crown of the bell when it is made. The clapper hangs from the staple by a baldrick fitting. This is a hoop of metal attached to its top by two or three (usually rusty) nuts and bolts, and often lined with a leather strip. If the bell has been quarter turned or if the local blacksmith has been at the clapper, you may find all manner of weird and wonderful modifications. If you are in doubt about the state of such fittings seek advice.

Iron staples can rust. This makes them expand and they can crack the bell in the process.

- Those attached to a central independent clapper bolt

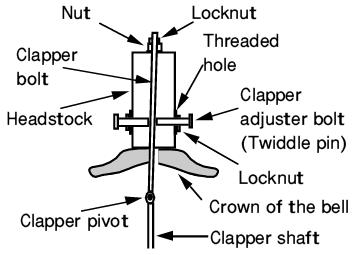

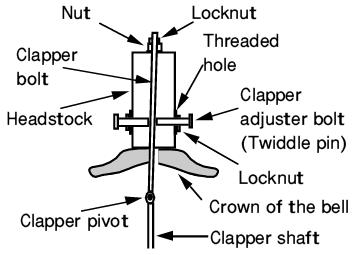

The clapper swings from a pin held in a staple. The staple is attached to a bolt that goes through a hole drilled in the top of the bell (often through the cannons as well) and right through the headstock.

The second method is now always used, and normally when re-hanging bells with cast-in staples they are drilled out as a precaution against cracking, and the clapper fitting changed to a central staple.

a: Do clappers need oiling or greasing?

If you have really ancient baldricks greasing will not achieve very much, but you might think it worthwhile to add a little grease to help reduce wear and to cut down the dreadful screeching noises they sometimes cause.

Older types of central staple often have a grease cap on the end of the pin on which the clapper swings. This cap needs a turn or two every three to six months to squeeze a little more grease into the bearing. It's quite a good idea to swing or wiggle the clapper sideways as you do this. It makes it easier for the grease to enter the bearing. When you can't turn the cap any more, remove it and refill it. It is quite common for the grease to solidify in which case you have to dismantle the assembly and clean it out. Modern fittings have no means of lubrication, and none is needed.

b: How do I know if the clapper bearings are worn?

As well as swinging fore and aft, the clapper can move a small amount in the other two directions: vertical and sideways. You can test this by trying to lift the clapper up and down and moving the ball from side to side. With baldrick fittings there will probably be quite a lot of movement in both directions, but there is not a lot you can do about it. If there is excessive sideways movement (maybe up to a foot) you should seek advice, since there is risk of damaging the bell. Vertical movement may be as much as a couple of inches in some cases. This may mean you need some sort of remedial work such as replacement of the leather liner. Seek advice.

With modern fittings there should be less than a quarter of an inch (6mm) of vertical play and probably less than an inch (25mm) of horizontal movement. Any more than this probably means the clapper needs re-bushing, which is a professional job.

c: What are twiddle pins for?

Bells with modern metal headstocks often have two horizontal bolts going into opposite sides of the headstock. They have a several names, but twiddle pins seems favoured. There is room for the clapper bolt to move within the headstock, and the twiddle pins fix its position within this range of movement. Moving one bolt out and the other in [225], you can move the clapper slightly and alter the striking of a bell.

Bells with modern metal headstocks often have two horizontal bolts going into opposite sides of the headstock. They have a several names, but twiddle pins seems favoured. There is room for the clapper bolt to move within the headstock, and the twiddle pins fix its position within this range of movement. Moving one bolt out and the other in [225], you can move the clapper slightly and alter the striking of a bell.

d: Should I take the clapper out of the bell?

Only if you need to and you know what you are doing. It can be done without special tools providing you take care, but it is not an easy job so only attempt it with an assistant and if you are sure you can do it safely. The weight, and awkwardness of manhandling the clapper assembly in a confined space, make the job difficult. It weighs a lot more than you might think, even on a modest sized bell. After loosening the nut and before your assistant removes it from the bolt, lift the clapper to push the bolt back up through the headstock. This makes sure you can support the full weight safely from below. When convinced you can support the weight, hold the clapper in situ while your assistant removes the nut and joins you in the pit [226] to help manoeuvre the clapper assembly clear of the bell (and yourself). The bolt and staple could be up to half a metre (a foot and a half) long. It can jack-knife when it gets clear of the bell, possibly onto your head or hands!

Replacing a clapper is more difficult than getting it out! Not only have you got to lift it 'uphill' but you have to get the tip of the bolt into the hole and aligned with it while doing so. When the bolt appears through the headstock, have a nut put on several turns before doing anything else. When you have drawn the clapper fully up into the bell, but before tightening the nut, check that the clapper swings correctly in the same plane as the bell. You can do this by eye looking along the length of the pit. As an additional check, see that the ball swings neatly into the centre of the depression it has worn on both lips of the bell.

When you tighten the nuts, the clapper may twist in the direction you turn the nut. If this happens hold the clapper ball firmly against the soundbow to prevent it from turning. If you can't stop it doing so, this is one of those rare occasions when you may use a stillson wrench, to grip the flight.

e: What is an SG-iron clapper?

SG means spheroidal graphite. SG iron is a modern alloy with mechanical properties suitable for clappers. Traditional clappers were of wrought iron. When wrought iron production ceased, bell hangers had to find a new material. Mild steel (commonly used for so called 'wrought iron' gates) proved unsuitable for clappers.

SG iron is now used for new clappers. You can easily tell SGI clappers from wrought iron ones. The shank and flight is normally circular in section (not octagonal), and the thick portion around the pivot may be extended. They are smoother, often with machined shanks. (Forging gives wrought iron a rougher surface) Early examples of SGI clappers were thicker and heavier than a typical wrought iron or modern SGI clapper, making them very distinctive. Some of these early clappers produced a slightly duller sound because the extra weight deadened the vibration a little.

f: What is a clapper stay?

It is a device used to silence the bell by preventing the clapper swinging. There are various forms. Some towers have a full set of clapper stays while others use rope to lash the clappers. See section 6.4i for a fuller description.

g: What is a clapper buffer?

It is a small plug of rubber inset in the ball of a clapper. Clapper buffers are fitted to some light bells to lift the clapper clear of the bell as soon as it has struck. This allows the bell to hum longer than it would normally if the clapper stayed in contact with the bell and deadened the sound.

Previous

Next

Next

Currently hosted on jaharrison.me.uk

Bells with modern metal headstocks often have two horizontal bolts going into opposite sides of the headstock. They have a several names, but twiddle pins seems favoured. There is room for the clapper bolt to move within the headstock, and the twiddle pins fix its position within this range of movement. Moving one bolt out and the other in [225], you can move the clapper slightly and alter the striking of a bell.

Bells with modern metal headstocks often have two horizontal bolts going into opposite sides of the headstock. They have a several names, but twiddle pins seems favoured. There is room for the clapper bolt to move within the headstock, and the twiddle pins fix its position within this range of movement. Moving one bolt out and the other in [225], you can move the clapper slightly and alter the striking of a bell.