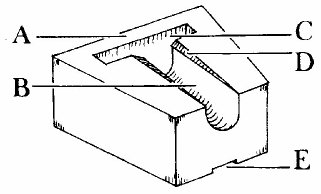

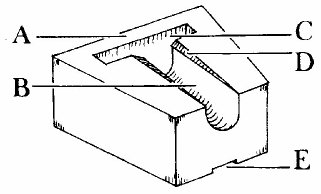

A = Brass block

A = Brass block The Tower Handbook

Plain bearings usually consist of a solid brass block with a rounded horizontal groove holding the gudgeon (see section 14.2) which turns in the groove. Older ones will be cut into the timber of the frame, while later ones will be mounted on a metal plate attached to the frame. There will be some sort of cover to the bearing, and this may vary from a length of timber fixed to the frame above the gudgeon through to metal covers with oil reservoirs filled with bits of cotton waste to act as wicks so the oil feeds slowly onto the gudgeon. The life of a plain bearing is probably in the region of 50 years, and since not many (if any) have been installed since the 1930s it is reasonable to assume that most are now 'past their sell by date'. Plain bearings are not self-aligning, so if they were not fitted absolutely accurately in the first place, or if the frame has distorted slightly over the years, the bearings or gudgeons will have worn. This will affect the go of the bell – sometimes quite dramatically.

Ball bearings consist of standard ball races in plummer [222] blocks attached to the frame via a metal base plate. The gudgeon fits into the ball race, which is self-aligning [223], so there is much less wear to all moving parts. There is often a grease nipple or plug on the bearing through which grease may be introduced into the housing. Modern fittings often omit this because of the damage done in the past by over enthusiastic steeple keepers over greasing (see below).

It depends on many things. If the bearings are badly worn, if there is a lot of frame movement or if the bells are rung a lot, oil will leak out more rapidly and need replacing more often. In the extreme you might have to do the job weekly in the summer or you might get away with every month. You will probably find that certain bells (particularly heavier ones) need more attention than others.

A = Brass block

A = Brass block

B = Rounded groove in which gudgeon turns

C = Oil reservoir channel

D = Chamfered edges to conduct surplus oil back into reservoir

E = Recess for inserting lever to remove bearing

Some bearings have a channel at the end of the gudgeon. This was intended as a reservoir for lubricant, but you will often find it has a bit of dirty rag soaked in caked up oil. Replace this, clean it out and add fresh lubricant.

Opinions vary, but castor oil or a thickish grade (SAE 90) mineral oil are OK. Do not mix the two types, so if you're not sure what was used before clean out the bearing and then refill it. You can also use a thinnish grease (maybe lithium-based). The choice of oil or grease depends to some extent on the state of the bearing and how exposed it is to the weather. Since you need lubrication all the year round anything that solidifies in the winter or runs away during the summer is not very suitable.

About every 15-20 years, or possibly not at all (see section 14.3e). Ball bearings are fitted with a grease seal, so that once installed they need hardly any attention. The grease serves little purpose as a lubricant and is more to protect against entry of dirt and moisture and to prevent rust.

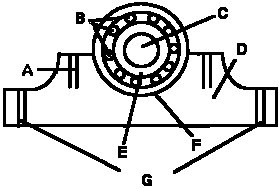

Typical ball bearing assembly

Typical ball bearing assembly

top cover, end plates and some ball bearings omitted for clarity)

A = Top cover bolt screws into hereEInner sleeve

B = Ball bearingsFOuter sleeve

C = Gudgeon pinGFixing holes for attachment to frame

D = Cast iron housing or plummer block

Remove the grease nipple or plug and have a look at the grease in the bearing. If it appears to be non-existent or very hard, then lubrication may be required. In more modern installations there is a plate screwed onto the back of the plummer block. You can remove this for a better inspection of the bearing (unless you can't get at the screws because the bearing of an adjacent bell is in the way). Even if you feel that more grease is needed, don't do anything until you've obtained some expert advice.

If you add grease unnecessarily you may force the seal. Once you have done that, grease will in future run out of the bearing (see section 14.3g). Probably the best advice is don't add anything, but clean out the bearing and replace the grease. This is not a job for an amateur.

The formulation of greases is changing all the time. Don't use an unsuitable grease (such as one which solidifies in winter). Seek advice before adding any lubrication to ball bearings (see section 14.3d).

Probably yes. The grease seal is damaged and it may need replacing, or the bearing itself may need renewal. The damaged seal could also mean the gudgeon is loose so it is worth checking this too. If grease has been coming out of the bearing for ages there may not be much of a problem, but if you're not sure get some advice. In any event clean up the excess grease (since if you don't it will get spread around and get on everything) and keep an eye on the bearing. You may have to add grease occasionally, but do it sparingly.

Check that the bearing and housing are not moving. In the case of timber frames where there is a metal plate resting on the frame, check that it is firmly attached to the frame. It is usually held by coach screws screwed into the timber. See section 14.12b for advice on loose coach screws.

Bearings on metal frames are unlikely to present many problems, but check the tightness of the bolts securing the housings to the frame just the same.

There is supposed to be a little lateral play on bearings, and if for some reason there is none, there may be a degree of pinching of the gudgeons (especially with timber frames). This may make the bell go badly. If you think you have this problem seek expert advice.

Currently hosted on jaharrison.me.uk