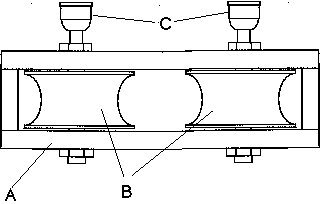

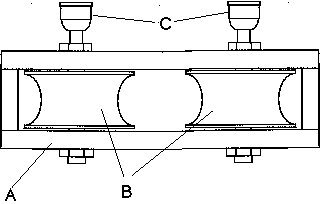

Typical older style pulleys

Typical older style pulleysThe Tower Handbook

There are two kinds of pulley. A ground pulley, fitted immediately below the wheel of every bell. It allows the rope to make a smooth transition between backstroke and handstroke. At handstroke the rope wraps round the underside of the wheel and turns through roughly a right angle so the pulley is essential. At backstroke the rope goes straight up and over the top of the wheel, so no pulley is needed, provided the rope hangs immediately below the edge of the wheel. Sometimes this is impractical so a second ground pulley is used to draw the rope in from the vertical before it passes down to the ringing room.

The other type of pulley is used where the layout of the frame places the ropes in significantly different positions from what is needed for a good rope circle below. These pulleys may be in the bell chamber or at other points between the frame and ringing room where the direction of the rope changes. If ropes are redirected very much they are said to be drawn. This often happens where new bells have been added to an existing installation.

Typical older style pulleys

Typical older style pulleys

A = Pulley block

B = Pulley

C = Grease cap

Freely turning trouble-free pulleys are as essential to the go of a bell as any other part of the fittings, but this is often overlooked. The ropes move through the pulleys at high speed and any friction on the ropes is multiplied by the size of the wheel to exert a significant influence on the bell. When checking pulleys, make sure you don't miss any hidden behind (or even in) the clock case or on the floor between the ringing room and the bell chamber.

Pulleys should spin easily and be free from dirt and excess grease. Older pulleys will be made of wood and may have a grease cap at the end of the bearing. This cap needs a turn or two every three to six months to squeeze a little more grease into the bearing. It's quite a good idea to spin the pulley as you do this. It makes it easier for the grease to enter the bearing. Every now and then you will have to remove the cap and refill it. Modern pulleys may be made of nylon which does not need lubrication. There are rumours that such pulleys are more likely to wear grooves, especially with synthetic ropes, but as with many rumours there does not seem to be much evidence. The main cause of pulley wear is when they stick and do not turn freely.

Watch out for a pulley which has been jammed for any length of time. The constant movement of the rope on one part can wear to an oval shape. Once you've freed it up people may feel odd sensations on the rope whilst ringing. Some of those 'square bearing' complaints may be due to the rope running over an egg-shaped pulley! If this is a problem either replace the pulley or get a wood turner to turn it circular for you.

Sometimes the rope wears a groove in the pulley wheel. A little wear may not cause problems but if the wear is bad the rope may sometimes stick in the groove and cause erratic handling problems. As above, replace or repair.

The only other fairly common problem with pulleys is where the rope becomes trapped between the pulley and its block. The pulley may be loose in the block, or the block may have become damaged to leave an excessive clearance between the two. If the problem lies with the block you may be able to repair it, but replacements are not hugely expensive.

Currently hosted on jaharrison.me.uk